Well-known player in the Norwegian aquaculture industry chooses HighComp yet another time.

In a powerful testament to composite excellence, Norwegian aquaculture giant Alsaker Fjordbruk has chosen HighComp’s GRP fish farming tanks for the third consecutive time, reinforcing their position as the industry’s preferred solution provider.

– This repeated trust from Alsaker Fjordbruk is both a tremendous compliment and a powerful validation of our solutions, says Fredrik Faye, VP sales at HighComp.

Alsaker Fjordbruk is the owner behind the fish farming facility Fjon Bruk. HighComp supplied the facility during a major upgrade in 2009 and will now contribute to their new expansion.

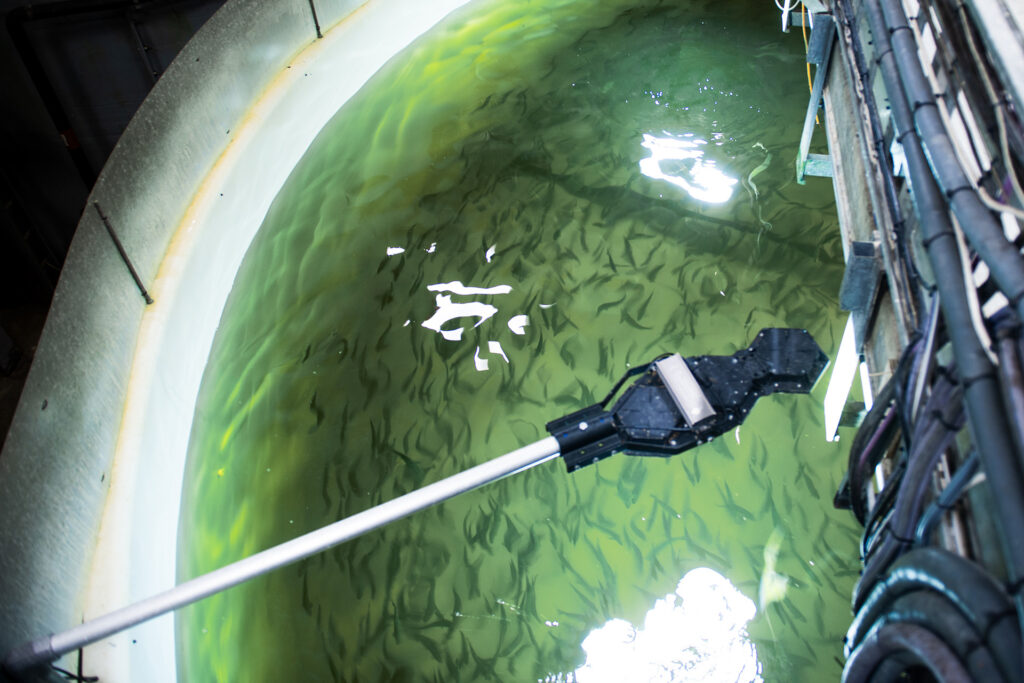

– We are now replacing some old three-meter fish tanks with new fish tanks. Since we have limited floorspace, we challenged HighComp to make six-meter fish farming tanks, but with a height of five meter. So these new fish tanks are not standard measure, explains department manager at Fjon Bruk, Svein Tore Flakke.

– While this new expansion is smaller in scale than the 2009 upgrade, it significantly enhances the facility’s capacity, Faye continues and adds that they’ve had a very good and open dialogue with Fjon Bruk over these years.

Located in Sveio, Fjon Bruk stands as one of Norway’s most advanced smolt facilities, supplying fish to food fish farms across the region. The new upgrade will, among other things, cut water consumption in half compared to the water consumption of the old fish farming tanks which is now being replaced.

– The idea behind the expansion is to get roof over the fish tanks. The fish tanks now being replaced are outdoor tanks, where we cannot control the light. When producing smolt, it is important to maintain stable temperature, water, and light, so that the fish do not smoltify too early or too late, Flakke explains.

– We received fish farming tanks from HighComp in the grow-out hall back in 2009, and we have experienced that these are strong, high-quality fish tanks. In addition, Alsaker Fjordbruk had an expansion at Bjølve Bruk, where HighComp delivered eight-meter fish tanks, and they work very well! That’s why we took inspiration from there and stretched them a bit in height so that the same setup would fit here. So far, we have had a good collaboration with HighComp. We bring them ideas that are not entirely standard, but they are openminded and find the solutions we need, Flakke praises.

The contract includes new aquaculture tanks, as well as additional equipment as dead fish-crate. The construction of the hall is currently ongoing. The fish farming tanks are expected to be delivered during the summer of 2026.

– We always aim to keep the installation time as short as possible. Our ability to manufacture fish farming tanks while the hall is being built significantly reduces overall project timelines, Faye explains.

HighComp’s success lies in its combination of cutting-edge technology and decades of expertise.

– The material itself hasn’t changed much over the years. But our highly skilled employees are continuously working on further developing and optimizing our solutions. Both to reduce costs and to ensure the products work even better for our customers. All our projects are individually tailored. We use vacuum infusion technology to ensure uniform resin distribution throughout the parts, minimizing voids and inconsistencies. This ensures consistent mechanical properties and improved performance.

Being a subsidiary company of CSUB, the world’s largest EPC-supplier of innovative Glass Fiber Reinforced Polymer solutions to the Oil & Gas industry, HighComp brings unmatched composite expertise to aquaculture.

– We draw on experience and knowledge from both industries to create products that are best in class. The benefits are clear: exceptional durability, minimal CO2 emissions, superior impact strength, and unlimited design flexibility.

HighComp’s track record of repeat customers extends beyond Alsaker Fjordbruk. Grieg Seafood in Newfoundland, Canada, represents another success story, having chosen HighComp for four separate facilities.

– Clients value the reduced construction time, but they’re equally impressed by the practical benefits. Our tanks feature an ultra-smooth finish that prevents bacterial growth and makes cleaning effortless. In addition, the fact that our fish tanks come in 4-6 large sections and has superior quality, minimizes the risk of damages or leakages.

With virtually zero maintenance requirements and a minimum 30-year lifespan, the long-term value of fish farming tanks in composite is exceptional.

– If you treat the product properly, it can last you much, much longer. Even tough it’s not common practice, the fish tanks are built in a way where you can dismantle them and reuse them somewhere else if you want to, Faye says.

Following a year affected by electricity costs and the Norwegian Salmon Tax, the aquaculture industry in Norway is showing strong signs of revival.

– Projects that’s been put on hold, are now starting to be put into action. Particularly when it comes to land-based food fish production, Faye says and elaborates: – That’s now a proven technology, which increases the interest from companies and investors.

HighComp’s solutions serves both land-based and marine fish farms.

– We’re seeing numerous exciting projects on the horizon, and our composite solutions are perfectly positioned to support them and the industry’s future growth.